- Home

- About

-

Products

- ProductsFuhua 16 ton special d

- Drum type film cleaning and in

- CNC brake pad (bending pad) dr

- CNC brake pad drilling machine

- CNC brake pad drilling machine

- Multi function CNC internal ar

- CNC brake pad external arc gri

- Brake pad (Mechanical) externa

- Brake pad limit line edging ma

- Brake pad sampler

- Other products

- Videos

- Custom

- News

- Contact

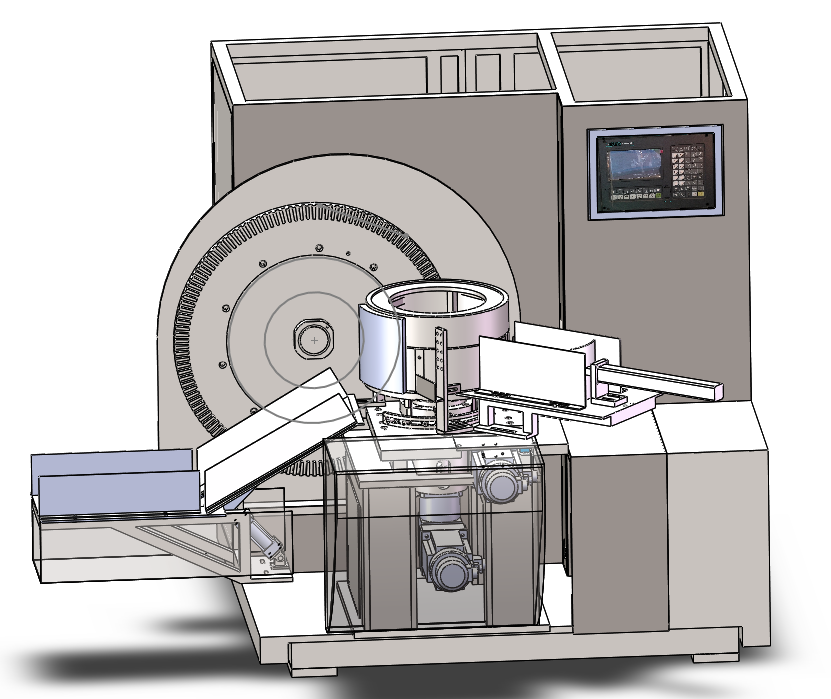

1. Overall structure and characteristics

Product model: MK-33-DYZ

Single machine size: 1800*1300*1500mm (length X width X height)

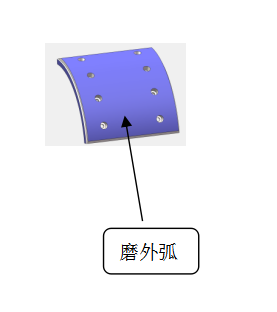

Main function: grinding outer arc

2. Processing content:

(Schematic diagram of processing location)

3. Main features:

1. Two-axis computer control system, high machining accuracy.

2. The hub can be disassembled, the replacement is quick and convenient, and the replacement can be completed within 15 minutes.

3. The hub is driven by a servo motor and a high-precision planetary gear reducer, with automatic indexing and automatic rotation.

4. It can grind thick slices or equal-thickness slices. Brake pads with the same inner arc do not need to replace the hub, and the hub does not need to be adjusted when grinding thick slices, which is directly guaranteed by the program.

5. The two-axis numerical control system is used to precisely control the clearance between the hub and the grinding wheel and the grinding wheel, and the size of the brake pad can be compensated and adjusted through the program.

6. The grinding wheel adopts sintered diamond technology, which has a large grinding volume, the diameter of the grinding wheel is 600-800mm, the processing line speed is high, and the surface quality is good.

7. The grinding wheel has a separate dust cover, and the dust extraction effect is more than 90%.

8. The grinding machine automatically flips the stacking mechanism, and the brake pads can be automatically stacked neatly.

9. A fully enclosed cover is added to the equipment to further isolate dust, and dust extraction and dust collection devices are installed, which is more environmentally friendly.

Fourth, equipment advantages:

1. The biggest advantage of this machine is that the wheel hub does not need to be adjusted, and it can process equal-thickness and unequal-thickness sheets (T-shaped sheets), which is different from the traditional external arc grinding by adjusting the shims on the hub to process unequal-thickness sheets.

2. The two-axis numerical control system is used to precisely control the clearance between the hub and the grinding wheel, and the size of the brake pad can be compensated and adjusted through the program. Just enter the data such as the central angle, radius, thickness and head of the brake pad, and the program can be automatically generated. The saved program can be called directly in the next production. The thickness of the brake pads can be fine-tuned by offsetting the reference coordinates. Compared with the traditional mechanical external arc grinder, it has the advantages of convenient operation, high precision and quick adjustment.

3. The modular workbench is used to facilitate product replacement and reduce costs.

4. The processing speed can be specified by the program, which is convenient to match the speed of the front and rear processes.

5. The grinder is equipped with dust extraction and dust collection devices, which are fully enclosed during work and are more environmentally friendly.

Five, the main technical parameters

(1) Processing range: R142~R245mm, width 30-240mm;

(2) Feed axis: 2-axis control, horizontal axis (X) stroke 100mm;

(3) Processing efficiency: 1 person can operate 3 sets;

(4) Diameter of grinding head: Φ800mm

(5) Spindle: Power 18.5kw Speed: 1500rmp

(6) Circular runout: 0.05~0.1mm;

(7) Servo motor: power 1.5~2.3KW, torque: 10Nm; rotary servo 16Nm;

(8) Dust extraction rate: 90%;

(9) CNC system: 2-axis control system;

Related Products

Related News

More>>- Director Luo of Zaoyang Science a... 2016-02-29

- Hubei Deyizhi Precision Machinery... 2020-05-08

- The specially invited representat... 2020-05-08

- Hubei Province announced the seco... 2020-05-08

- Deyizhi's products are famous ove... 2020-05-05

- Lei Jianbin and other leaders of ... 2018-12-19

- Hubei Deyizhi Precision Machinery... 2017-05-12

- Zaoyang Invention Association was... 2016-11-08

- Mr. Wang Yao, President of China ... 2016-08-21

- Zaoyang City is currently in full... 2016-03-11