- Home

- About

-

Products

- ProductsFuhua 16 ton special d

- Drum type film cleaning and in

- CNC brake pad (bending pad) dr

- CNC brake pad drilling machine

- CNC brake pad drilling machine

- Multi function CNC internal ar

- CNC brake pad external arc gri

- Brake pad (Mechanical) externa

- Brake pad limit line edging ma

- Brake pad sampler

- Other products

- Videos

- Custom

- News

- Contact

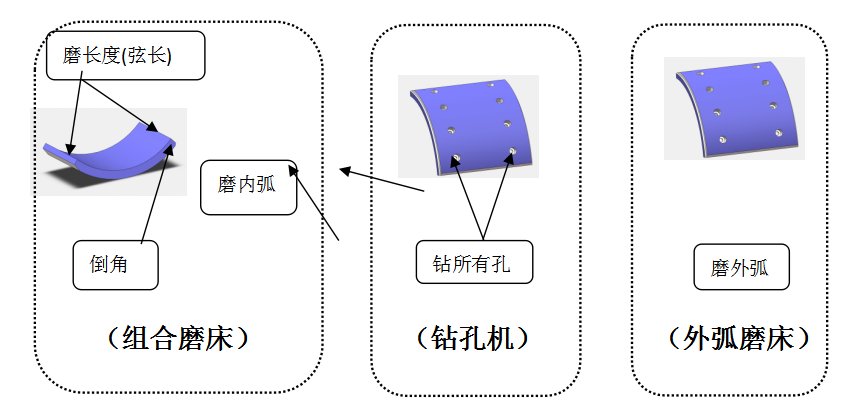

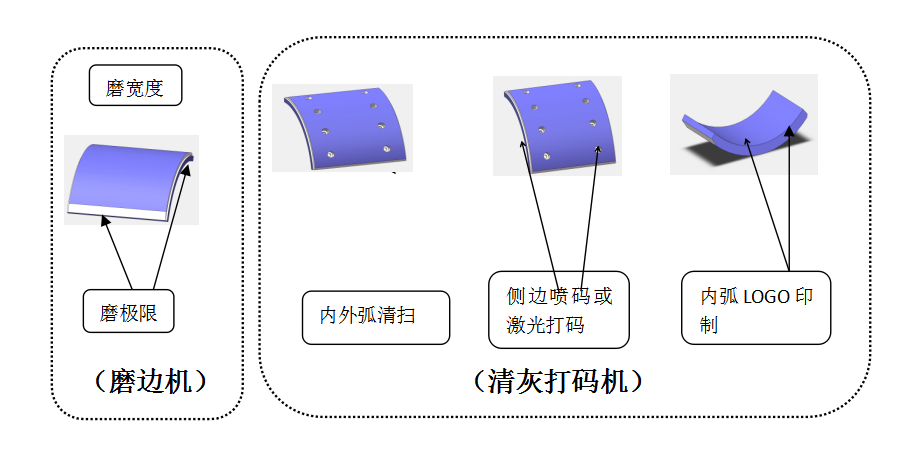

1. Processing content

1. Grinding chamfering 2. Grinding length 3. Grinding inner arc 4. Drilling hole 5. Grinding outer arc 6. Grinding limit 7. Grinding width 8. Inner and outer arc cleaning and coding or laser marking 9. Other customer requirements Project increase or decrease

2. Efficiency of a single pipeline

2000-4000 tablets/class.

According to the different materials of the brake pads and the number of holes, the efficiencies are as follows:

1-6 holes: 4000 pieces/class

7-12 holes: 3000 pieces/class

12-18 holes: 2000 pieces/class

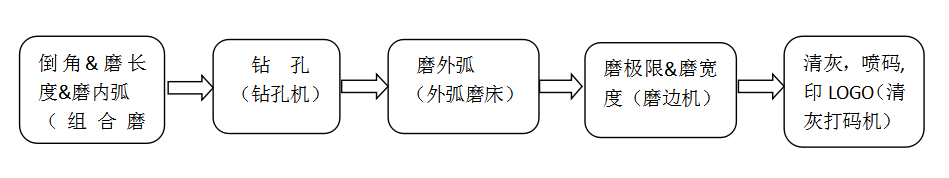

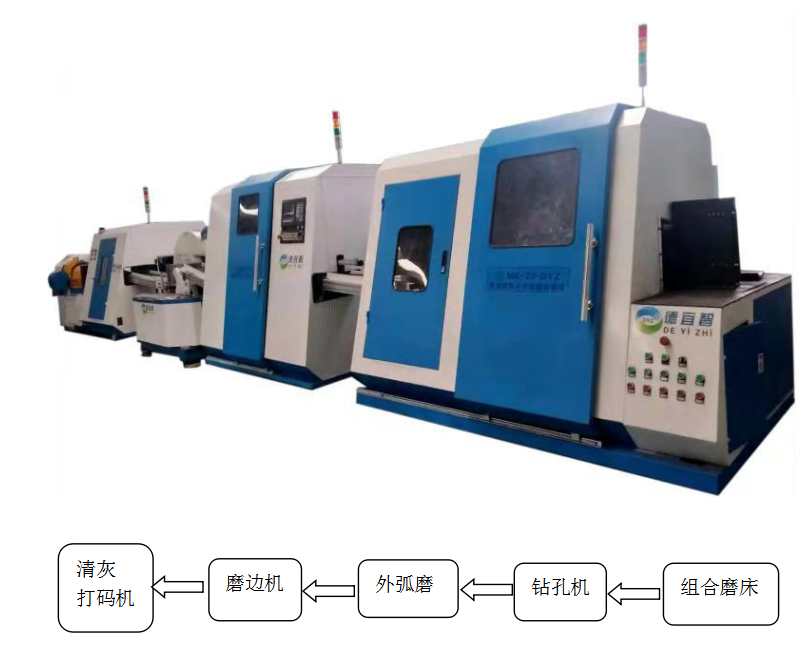

3. Process flow

The processing contents of each process are described as follows:

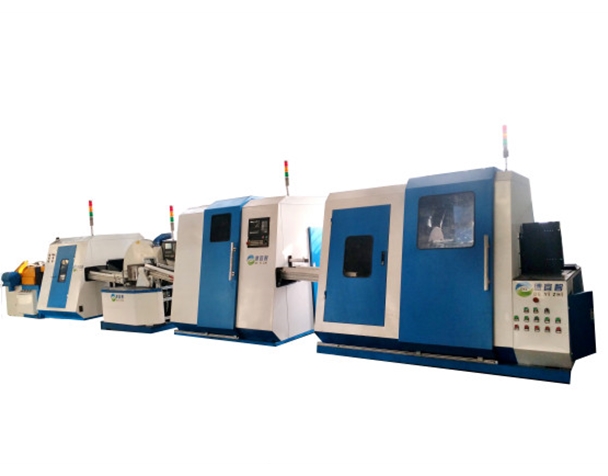

4. Pipeline layout

This assembly line uses materials to be conveyed from right to left, and each process is linked by a conveyor belt. The input end of the feeding is the raw material of drum brake pads, and the output of the assembly line is the finished brake pads, which can be directly connected to the packaging line.

5. Introduction to the assembly line

This assembly line is composed of 5 machine tools, which adopts the most optimized scheme and the least number of machines, which can realize automatic loading and unloading. The processing contents include grinding chamfering, grinding length, grinding inner arc, drilling, grinding outer arc, grinding limit, grinding Width, inner and outer arc cleaning and coding, LOGO printing, etc. Each machine tool is connected by a conveyor belt, and the speed can be adjusted. Each machine can be adjusted individually. The total length is about 11 meters, and the size of the whole machine can also be adjusted according to customer needs. The production line overcomes the defects of traditional production equipment such as positioning, clamping, dust extraction (collecting), and machining accuracy. Due to the equipment positioning, clamping, pneumatic mode, and digital control mode for movement mode, the product has high machining accuracy and stable operation. , Dust extraction and dust collection are carried out by means of dust particle separation, which can efficiently extract dust and collect wastes, realize clean production, and the collected scraps can be reused. Each machine tool is equipped with a protective cover and a dust extraction pipe, which can extract up to 95% of the dust. The whole machine has a transparent protective cover to isolate the dust again. The whole process of this assembly line is automatic loading and unloading, which can realize one or two people to operate multiple lines, saving labor costs. The main parameters and performance of each machine tool are briefly introduced below.

5.1 Internal arc combination grinder

Product model: MK-23-DYZ

Single machine size: 2800*1400*1600mm (length X width X height)

3D display of the main structure:

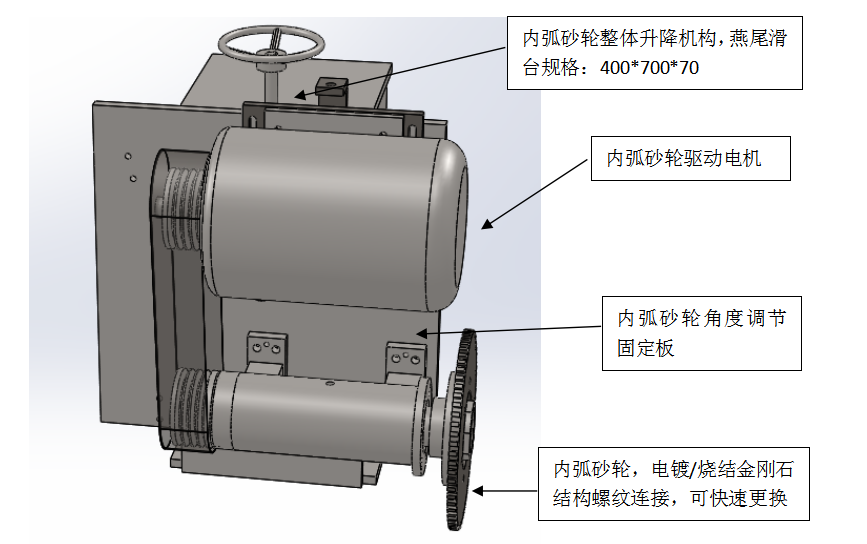

Internal arc grinding structure (can be vertically lifted 150mm, can be moved back and forth 50mm, and can be rotated at an angle of 0-10 degrees)

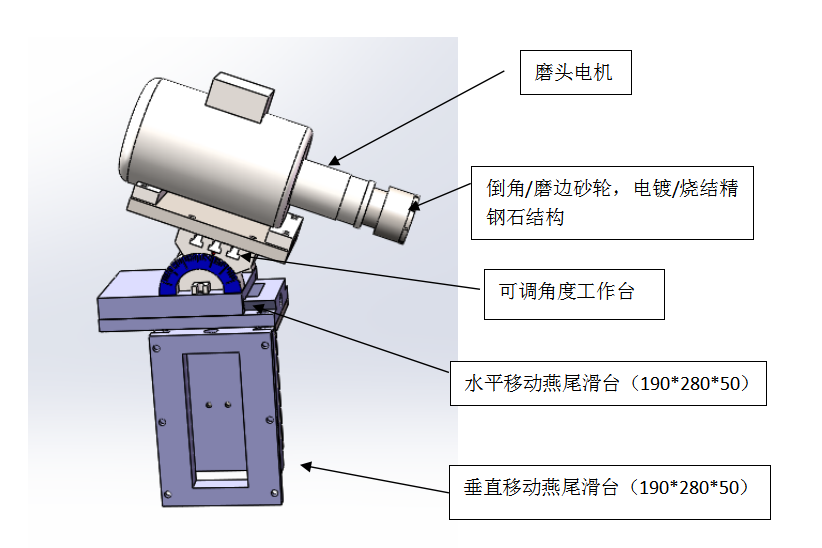

Chamfering and edging structure (can be vertically lifted 150mm, can be moved back and forth 50mm, and can be rotated at an angle of +/- 45 degrees)

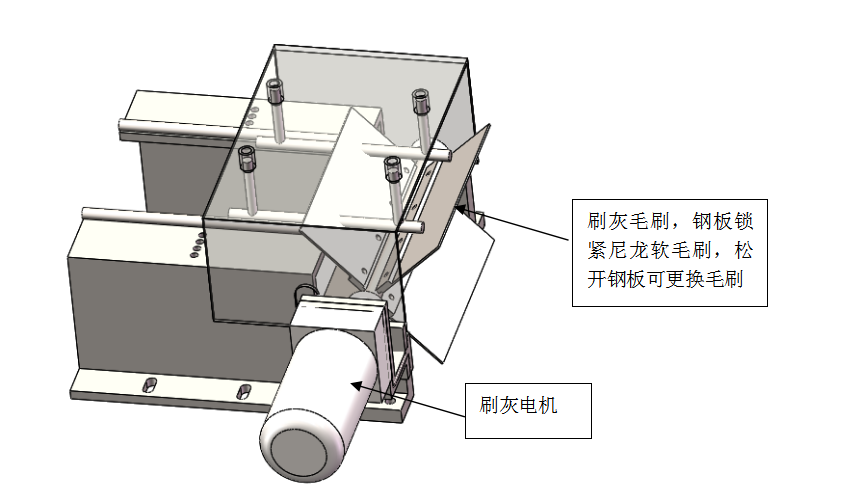

Brush dust structure (brush inner arc, press up and down adjustable)

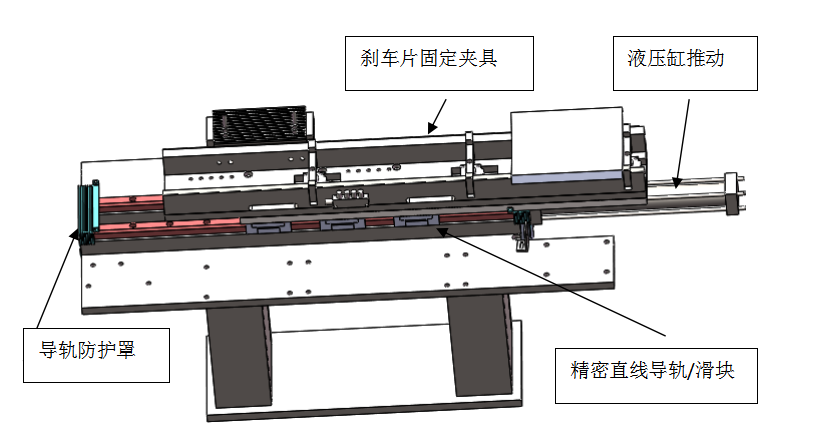

Brake pad moving mechanism (after the brake pad is positioned and clamped on the fixed fixture, it moves with the fixture, and there is no displacement between the fixture and the brake pad during processing)

Main functions: grinding chamfering, grinding length, grinding inner arc (the processing content can be seen on the first page)

main feature:

1. This model integrates various functions of chamfering, grinding length and grinding inner arc, saving space and shortening the length of the assembly line.

2. The feeding mechanism adopts hydraulic transmission, cylinder clamping and automatic feeding. The movement of the whole machine is controlled by PLC, and the program has been built in. The length and width of the feeding mechanism can be quickly adjusted, and can be adapted to different specifications of brake pads without replacement.

3. The chamfering mechanism uses two grinding wheels driven by a motor to rotate at high speed to grind the chamfers on both sides of the brake pads at the same time, with symmetrical processing, stable grinding, low vibration and high machining accuracy. During grinding, the brake pads are clamped by the cylinder, the brake pads and the fixture are relatively stationary, and the fixture moves in parallel along the precise linear guide rail to further improve the machining accuracy. The grinding wheel adopts electroplating/sintered diamond grinding wheel, which has large cutting capacity and long grinding life. Grinding wheel adjustment adopts dovetail sliding seat, and is equipped with digital display scale, the scale resolution is 0.01mm, and the adjustment accuracy is 0.02mm.

4. The length grinding mechanism adopts two grinding wheels driven by the motor to rotate at high speed to grind the two length sides of the brake pads at the same time, with symmetrical processing, stable grinding, low vibration and high processing accuracy. During grinding, the brake pads are clamped by the cylinder, the brake pads and the fixture are relatively stationary, and the fixture moves in parallel along the precise linear guide rail to further improve the machining accuracy. The grinding wheel adopts electroplating/sintered diamond grinding wheel, which has large cutting capacity and long grinding life. Grinding wheel adjustment adopts dovetail sliding seat, and is equipped with digital display scale, the scale resolution is 0.01mm, and the adjustment accuracy is 0.02mm.

5. The internal arc grinding adopts the structure of sintered diamond grinding wheel. The inclination angle of the grinding wheel can be adjusted within the range of 0-10 degrees. The grinding wheel has a detachable structure, which is very convenient for replacement and adjustment. When grinding, the brake pads and the fixture are compressed by the cylinder, there is no relative displacement, and the grinding precision is high. The fixture slides in parallel along the precision linear guide, with large bearing capacity and high precision.

6. The internal arc grinding power mechanism is integrally fixed on the dovetail sliding table that can be raised and lowered. The height of the grinding wheel can be adjusted by loosening the locking screw.

7. Each grinding wheel has an independent dust extraction pipe, which can extract up to 90% of the dust at one time.

8. A dust brushing mechanism is added at the rear of the equipment to initially deal with the inner arc dust.

9. The equipment is equipped with a fully enclosed cover to further isolate dust, and is equipped with extraction and dust collection devices, which is more environmentally friendly.

10. The equipment and the machine tool in the next process are connected by a conveyor belt.

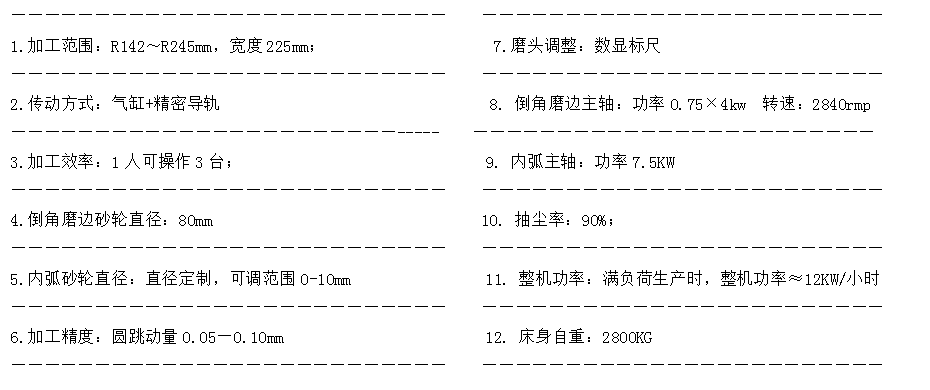

Equipment technical parameters:

各工序加工内容说明如下:

四.流水线布局

本流水线采用物料从右向左输送,各工序间用输送带链接,上料输入端是鼓式刹车片毛胚料,流水线输出为刹车片成品,可以直接接包装线。

五.流水线简介

本流水线由5台机床组成,采用最优化的方案,最少的机台,可以实现自动上下料,加工内容包含磨倒角、磨长度、磨内弧、钻孔、磨外弧、磨极限、磨宽度、内外弧清扫打码、LOGO印制等。各机床间采用输送带连接,速度均可调。每台机床均可以单独调整。总长约11米,也可以根据客户需要调整整机尺寸。该生产线克服传统的生产设备定位、夹紧、抽(集)尘、加工精度等缺陷,由于设备定位、夹紧、采用气动方式、运动方式采用数字化控制方式,使产品的加工精度高且运行稳定,抽尘和集尘采用粉尘颗粒分离方式进行,可高效抽尘和收集废料,实现清洁化生产,收集的碎料还可重复利用。每台机床均设有护罩和抽尘管,抽尘达95%,整机有透明防护罩,再次隔离灰尘。本流水线全过程自动上下料,可以实现一人或两人操作多条线,节约人力成本。下面简要介绍下各机床的主要参数和性能。

5.1内弧组合磨床

产品型号:MK-23-DYZ

单机尺寸:2800*1400*1600mm(长X宽X高)

主要结构3D展示:

内弧磨结构(可垂直升降150mm,可前后移动50mm,可旋转角度0-10度)

倒角磨边结构(可垂直升降150mm,可前后移动50mm,可旋转角度+/-45度)

刷灰结构(刷内弧,压紧上下可调)

刹车片运动机构(刹车片在固定夹具上定位夹紧后,随夹具一起运动,加工中夹具与刹车片无位移)

主要功能:磨倒角,磨长度,磨内弧(加工内容可看第一页图示)

主要特点:

1.本机型集倒角、磨长度、磨内弧多种功能为一体,节省空间,缩短流水线长度。

2.上料机构采用液压传动,气缸夹紧,自动上料,整机运动采用PLC控制,已内置好程序。上料机构长度宽度均可快速调整,不需更换,即可适应不同规格刹车片。

3. 倒角机构采用两个由电机带动高速旋转的砂轮同时磨削刹车片两边倒角,对称加工,磨削平稳,振动小,加工精度高。磨削时刹车片由气缸夹紧,刹车片与夹具相对静止,夹具沿精密直线导轨平行移动,进一步提高加工精度。砂轮采用电镀/烧结金刚石砂轮,切削量大,磨削寿命长。砂轮调整采用燕尾滑座,并配有数显标尺,标尺分辨率0.01mm,调整精度0.02mm。

4. 磨长度机构采用两个由电机带动高速旋转的砂轮同时磨削刹车片两长度边,对称加工,磨削平稳,振动小,加工精度高。磨削时刹车片由气缸夹紧,刹车片与夹具相对静止,夹具沿精密直线导轨平行移动,进一步提高加工精度。砂轮采用电镀/烧结金刚石砂轮,切削量大,磨削寿命长。砂轮调整采用燕尾滑座,并配有数显标尺,标尺分辨率0.01mm,调整精度0.02mm。

5.内弧磨采用烧结金刚石砂轮结构。砂轮倾角角度可在0-10度范围内调整。砂轮可拆卸结构,更换和调整十分方便。磨削时刹车片与夹具用气缸压紧,无相对位移,磨削精度高。夹具沿精密直线导轨做平行滑动,承载力大,精度高。

6.内弧磨动力机构整体固定于可升降的燕尾滑台上,松开锁紧螺丝,可以调整砂轮高度,调整高度0-100mm,以适应不同内弧规格刹车片。

7.每个砂轮均有独立的抽尘管,一次抽尘达90%。

8.设备尾部新增刷灰机构,初步处理内弧灰尘。

9.设备增加全封闭外罩,进一步隔离灰尘,加装抽排、集尘装置,更环保。

10.设备与下工序机床采用输送带连接。

设备技术参数:

Related Products

Related News

More>>- Director Luo of Zaoyang Science a... 2016-02-29

- Hubei Deyizhi Precision Machinery... 2020-05-08

- The specially invited representat... 2020-05-08

- Hubei Province announced the seco... 2020-05-08

- Deyizhi's products are famous ove... 2020-05-05

- Lei Jianbin and other leaders of ... 2018-12-19

- Hubei Deyizhi Precision Machinery... 2017-05-12

- Zaoyang Invention Association was... 2016-11-08

- Mr. Wang Yao, President of China ... 2016-08-21

- Zaoyang City is currently in full... 2016-03-11